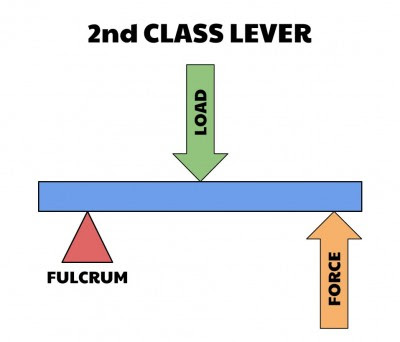

There are three classes of levers—the class is determined by where the load, fulcrum, and force are located.

For second-class levers, the load is usually located between the fulcrum and the force.

The closer the location of the load to the fulcrum, the easier it is to lift the load.

On the flip side, the closer the location of the effort in regards to the fulcrum, the more the effort that will be needed to lift or move the load.

The following are some common examples of second-class levers.

1. Wheelbarrow

A wheelbarrow is a classic example of a second-class lever.

The fulcrum of a wheelbarrow is at the wheel which is usually on the extreme front.

The use of the wheelbarrow exerts effort on the handles which are behind the placement of the load. This means the load is in between the fulcrum and the effort.

2. Staplers

Staplers are often misconstrued to be a first-class lever. The best way to know that it’s a second class lever is to remember that for second class levers, the load must be situated between the fulcrum and the effort.

When you are stapling papers, you apply force on the open end of the stapler which makes it close at the hinge.

This makes it drive the load (the staple) through the paper. So, the load is not the paper but the staple.

3. Doors or gates

A door or a gate is another good example of a second-class lever. The hinges of the door or gate are the fulcrum while the load is the door.

The person pushing or pulling the door open or shut is the one applying the force.

This places the load in between the fulcrum and the lever thereby making it a second class lever.

4. Bottle Openers

When using a bottle opener to open a bottle, it will function as a second-class lever.

In this case, the fulcrum will be at the end of the bottle opener that is placed on the head of the crown.

The fulcrum is created by the movement of the hand as you apply force and push the opener up to remove the crown from the bottle.

5. Nutcracker

A nutcracker is also a second-class lever. When using this tool to crack nuts, the fulcrum is at the hinge that joins the two pieces of metal to form the device.

To work it, you place the nut in between the metal rods and apply force on the extreme side away from the fulcrum.

So, just like the wheelbarrow and other examples of second-class levers, the load will be at the center of the force and fulcrum.

6. Nail Clippers

Second class levers magnify the effort and that is why they are placed at the opposite end of the fulcrum and the lever.

A nail clipper is an awesome illustration of this because it has two levers that work together to increase the mechanical advantage.

This makes it possible for one to clip tough nails without using too much force.

7. Oar

The oar of a boat is also a second-class lever. Even though some view the oarlock as the fulcrum, the real fulcrum is the water because that is where the oar moves either backward or forward and thus steers the boat in the desired direction.

Meanwhile, the oarlock is the load while the paddler is the source of the force which makes it a second class lever.

8. Trolley

The trolley uses the same working principle as the wheelbarrow and they are both second-class levers.

Just like wheelbarrows, the wheel is the fulcrum while the effort is applied on the handlebars by the person who is pushing the trolley.

The load is the goods the person is using the trolley to transport.

9. Crowbar

A crowbar is a versatile tool that can fall in all three classes depending on how you are using it.

When using the flat side, the crowbar can be said to be a second-class lever.

The thing you are prying or lifting will be the load that will come in between the pivot and the effort thereby making it a second class lever.

10. Pneumatic Tires

The pressure of pneumatic tires has to be maintained and one common way of keeping them inflated is by using a foot pump.

The foot will provide force and input motion at one side of the lever and a fulcrum at the other end.

The pneumatic pump is typically connected to the lever very close to the fulcrum.

Closing Thoughts

As we have seen, some tools can be in any of the three classes depending on how they are used.

The thing to remember is the fact that class two levers have the load in between the load and fulcrum.

So as long as this is the case, the machine will pass for a second class lever.